Hand-Finished, CNC-Supported Craftsmanship for a Perfect Fit

When it comes to custom bodywork, sometimes it’s about precision. Other times, it’s about patience. For this build, it was both. We’ve just completed the final stages of creating a sidepod Sleeping plug for the Ford Transit MK6 (pre-2014)—a process that’s been a proper journey through fibreglass, foam, filler, and frustration.

From CNC Skeleton to Final Plug

The process began with a CNC-cut skeleton to give us an exact structure to work from. Rather than using just timber or clay, we experimented with multiple build-ups including:

-

High-density foam and filler

-

Solid timber carved and shaped

-

Sanders, grinders, and elbow grease

In the end, the foam and filler combo gave the cleanest and most manageable results. After building out the basic form, we skimmed the entire surface with filler to refine the shape. We learnt a lot from making

Prepping for Mould Perfection

Once we had the shape locked in, the surface was treated to a full coat of high-build 2K primer. We then began the patient work of flat sanding, starting with 120 and refining to 400 grit. Every minor imperfection was picked up and corrected using stopper, making sure we had a blemish-free finish.

A Lesson in Sunlight and Shrinkage

Here’s the part where it didn’t go quite to plan…

After applying a final top coat, we left the plug outside. Initially to dry in the shade, we forget about it being out side so 2 hours later The sunlight shrunk the wood core, causing unexpected warping. It literally cooked it. It was a proper setback—we had to sand the whole piece back again and start the final finishing process from scratch. We hope to say this was a great lesson and might of just helped to create the ultimate plug ready to take our mould from. Having being tested with heat prior to fiberglass it and the chemical heat doing the same. Also some dripping from the gun because of a blockage.

That’s fibreglass work for you: unforgiving, but worth it when done right.

Final Prep Before Moulding

We’re now at the final stage—ready for the last coat of paint before a full polish to mirror-finish. Once that’s done, we’ll take the mould and begin limited production runs of the finished sidepods.

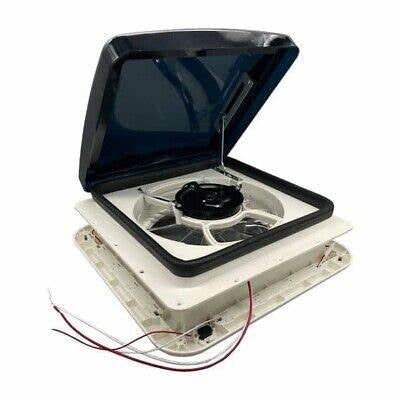

Sleeping Pod Frame and Strength Testing

This sleeping pod design has a 150 mm projection, allowing for a 1950 mm internal bed length—plenty of room to stretch out. We’ll include full image sets showing what we’ve created so far.

The internal bed frame was built using 60 x 40 x 3 mm aluminium, giving an extremely strong yet lightweight structure. For added support, we originally included a 76 x 76 x 3 mm slide-out beam, but through real-world testing—including someone over 20 stone in weight—we found that the 60 x 40 section was more than enough. The slide-out wasn’t necessary after all.

We cut out the side prior to wedding in a custom frame for the bed to slide.

Want One for Your Transit MK6?

These fibreglass sidepods will be available in small batches through our website. You’ll be able to:

-

Pre-order directly from the product page

-

Sign up for notifications when stock is released

-

View all images of the build process

1 comment

Still available? Can i order a one on it’s own ?