Introducing Our New Van Racking Configuration Tool — Built for Accuracy, Built Around You | Custom Solutions UK

Discover the new Custom Solutions UK Van Racking Configuration Tool. Built to capture exact measurements, toolbox types, drawers, trays, and storage requirements with full accuracy. No generic templates — a future-proof system designed around your actual tools and workflow.

Why We Built a New Configurator

Most configurators online are “pick a van → pick a rack → checkout.”

That might work for cheap, generic metal shelves — but not for professional racking designed around real tools, real trades, and real workflows.

Our systems are precision-built.

Your tools aren’t generic.

Your van isn’t generic.

Your workflow isn’t generic.

So we built a configurator that isn’t generic either.

The new Custom Solutions UK Configuration Tool captures exact, structured, build-ready data — the same way a designer or engineer would gather it.

This isn’t a sales form.

It’s a real design intake system.

Find the link here

The Tool Works in Five Clean, Logical Steps

1. Contact Information

Straightforward: your name, phone, email, and trade.

Not just for admin — this information is used to tailor recommendations later, such as:

-

Joinery → Festool / Bosch L-BOXX / SH3 drawer options

-

Plumbing → Milwaukee / Dewalt Tough / false floor storage

-

Boiler servicing → SH2 mid drawers + small parts trays

It’s simple but foundational.

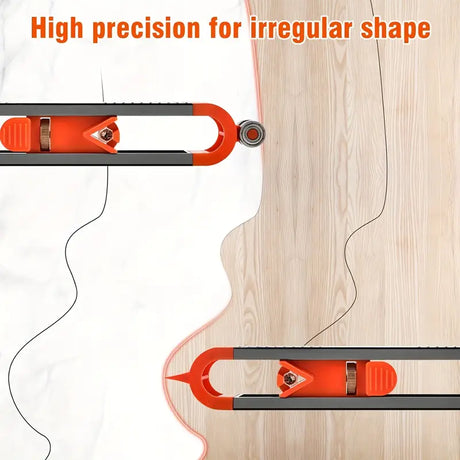

2. Van Geometry (The Most Important Step)

This is where most racking systems fail.

Our tool captures real internal measurements, not guesses.

You enter:

-

Internal install height (mm)

-

Right-hand install length (mm)

-

Optional left-hand length if you want dual storage

-

Van make/model for context

The system then:

-

Calculates your safe height band (1000 / 1200 / 1500 / 1775).

-

Ensures designs never exceed your real internal height.

-

Locks your install length as the actual reference for all unit widths.

No generic templates.

No “should fit.”

This is precise.

3. Toolbox Systems (Your Tools Define the Build)

Toolbox systems drive unit widths, shelf counts, and design layout more than anything else.

The configurator lets you choose up to three system brands:

-

Festool

-

Makita

-

Dewalt TSTAK

-

Dewalt Tough

-

Milwaukee

-

Bosch L-BOXX

-

Other (free text if needed)

It also collects:

-

Total toolbox quantity

-

Optional model information

-

Whether you need chop saw storage

From these choices, the tool automatically understands:

-

Your required unit widths

-

Your storage density

-

Whether SH2 or SH3 drawer tiers should be considered

-

How many shelves your layout will require

This is not a checkbox gimmick — toolbox data directly shapes the engineering.

4. Drawers, Trays & Add-Ons (Fully Quantified)

For the first time, you can specify:

Drawers

-

Small

-

Medium (SH2)

-

Large (SH3)

Trays

-

Small

-

Medium

-

Large

-

Linked to SH3 shelves only

Add-ons

-

Rail tray

-

False floor

-

End unit

-

Level box storage

-

Evo catches

-

Custom build notes (e.g. “build around Van Vault slider”)

The tool doesn’t just capture “yes/no.”

It captures quantities, which let us:

-

Calculate included vs extra shelves

-

Map drawer stacks to SH2 or SH3

-

Understand the complexity of your install

-

Generate accurate part schedules later

This is exactly how a designer builds a spec by hand.

5. Final Review & Automatic Configuration Code

The tool generates:

-

A clean summary

-

A full JSON configuration object

-

A build-style SET code:

This style code reflects:

height band + install length + primary brand + range level.

You get:

-

A clear, printable summary

-

A complete design brief

-

Photos attached (if uploaded)

-

An optional “Request 3D Design” tick box

-

An email with all details sent to our designers automatically

Your configuration becomes a project instantly.

Built to Eliminate Confusion, Guesswork, and Back-and-Forth

Here’s what the new configurator fixes:

No more vague budgets

Instead of fake price ranges, we use design profiles:

-

Concept (shelves)

-

Unique (toolbox ready + SH2 drawers)

-

Pro Unique (full SH3 future-proof storage)

This keeps things transparent and accurate — not misleading.

No more “generic" installs

Every detail is captured:

-

Height band

-

Toolbox width

-

Unit count

-

Drawer/tray quantities

-

Van geometry

-

Layout (right or dual)

-

Add-ons

This is the exact information needed to build a professional racking system.

No more wasted time

Our designers receive:

-

A full JSON file

-

Your summary

-

Your measurements

-

Your photos

-

Your 3D request (if selected)

No repeated questions.

No back-and-forth emails.

No incorrect assumptions.

What This Means for You

Faster quotes

We don’t start from scratch each time.

Your configuration arrives clean and complete.

Better designs

We design from data, not guesswork.

Fewer mistakes

Wrong heights, wrong fits, wrong units — eliminated.

Future automation

This configurator is the foundation for our next phase:

-

Automatic SET matching

-

Automatic SET generation

-

Automatic product creation in Shopify

-

Automatic price generation

-

Automatic CNC parts scheduling

The work you did with your form pushes us directly toward that future.

A Trade-First Configurator

This tool wasn’t built to sell shelves.

It was built to design real storage solutions for real tradespeople with real tools.

Plumbers, joiners, electricians, carpet fitters, boiler engineers, locksmiths, landscapers — every trade has different needs.

This configurator finally respects that.